Anti-Reflective Glass (AR Glass)

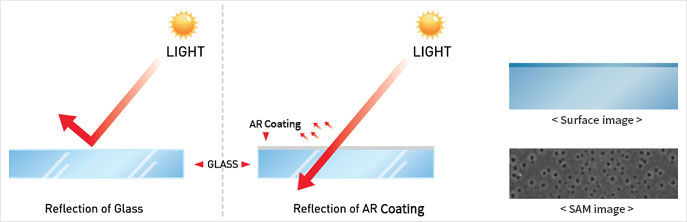

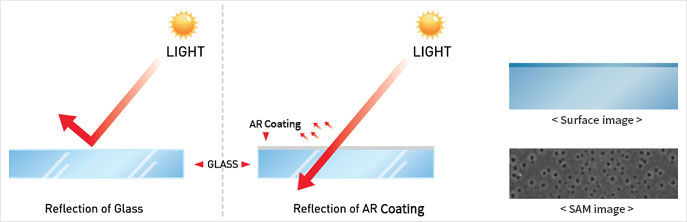

Anti-Reflective Glass is a glass in which SiO2/TiO2 is physically or chemically deposited

on the surface of the glass, and can improve the resolution of displays

by increasing the transmittance and reducing the reflectance, thus realizing high-definition images.

Anti-Reflective Glass is deposited on the glass itself rather than coated with a film,

thus causing no fear of peeling or deterioration.

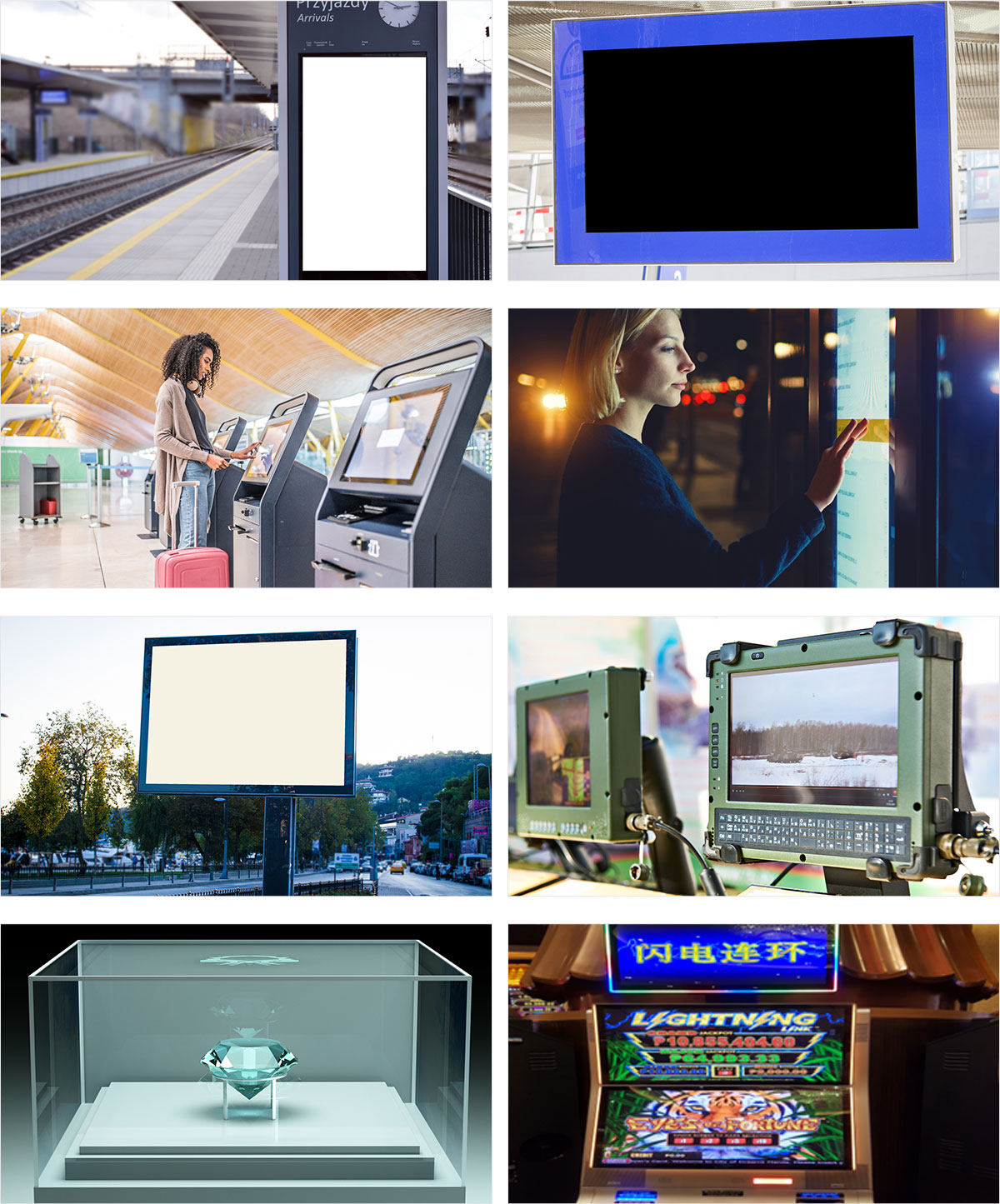

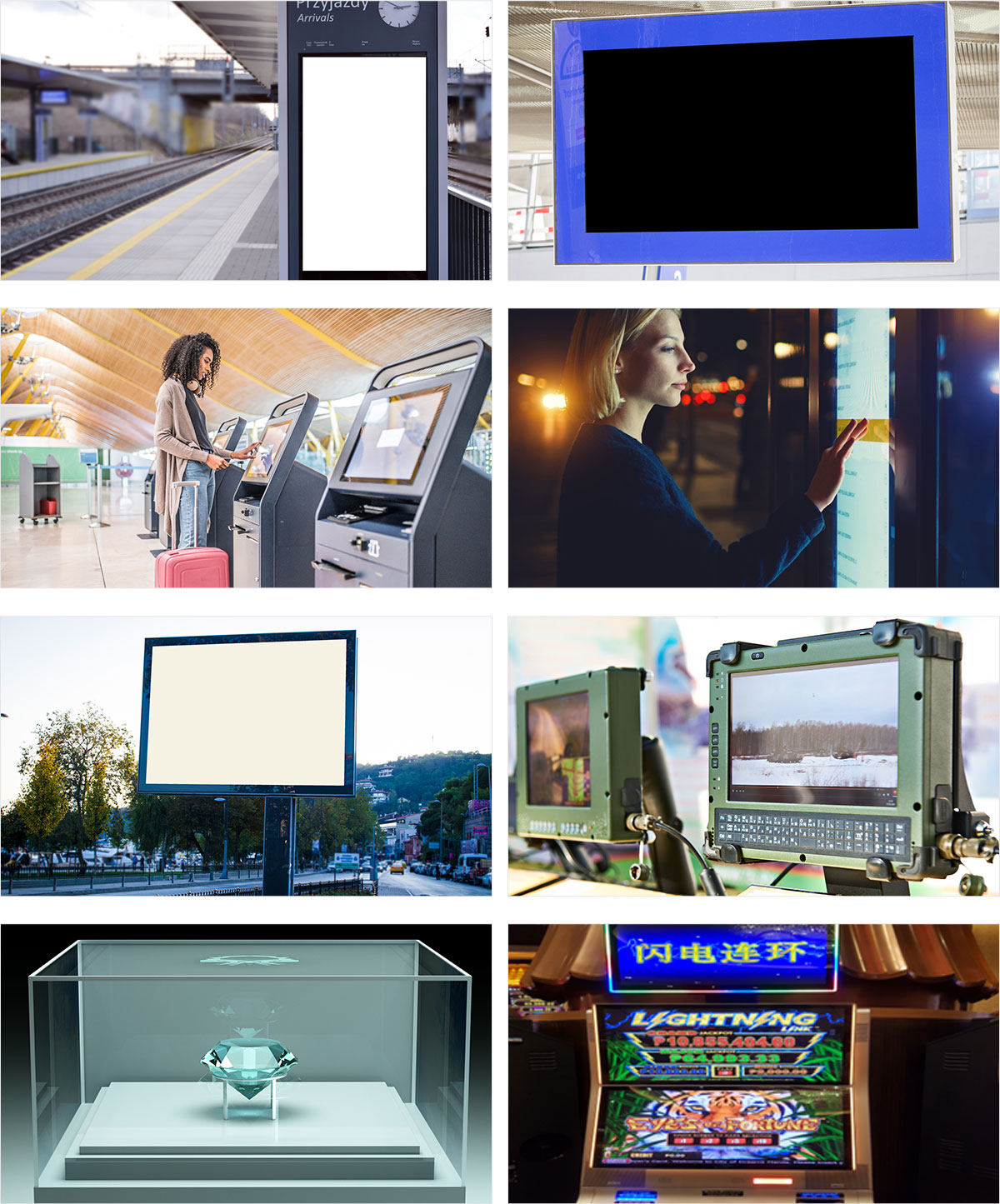

SunTec Co., Ltd. is applying Anti-Reflective Glass to a number of products

and various fields according to the characteristics using the processing methods

of in-line sputtering coating, E-BAM coating, and dipping coating.

Anti-Reflective Coating

-

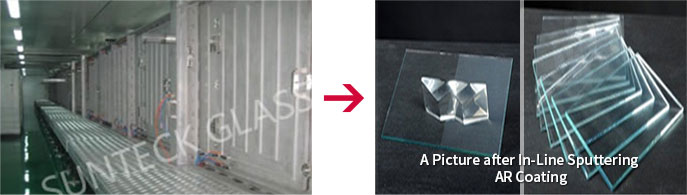

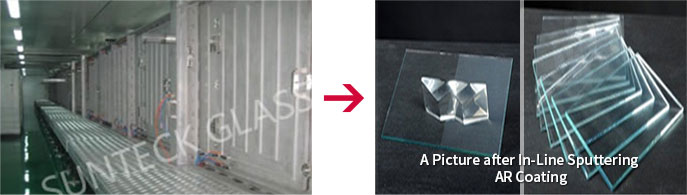

In-Line Sputtering Coatin

- Single-Sided Two-Layer Coating

- Single-Sided Four-Layer Coating

- Double-Sided Four-Layer Coating

- Double-Sided Eight-Layer Coating

-

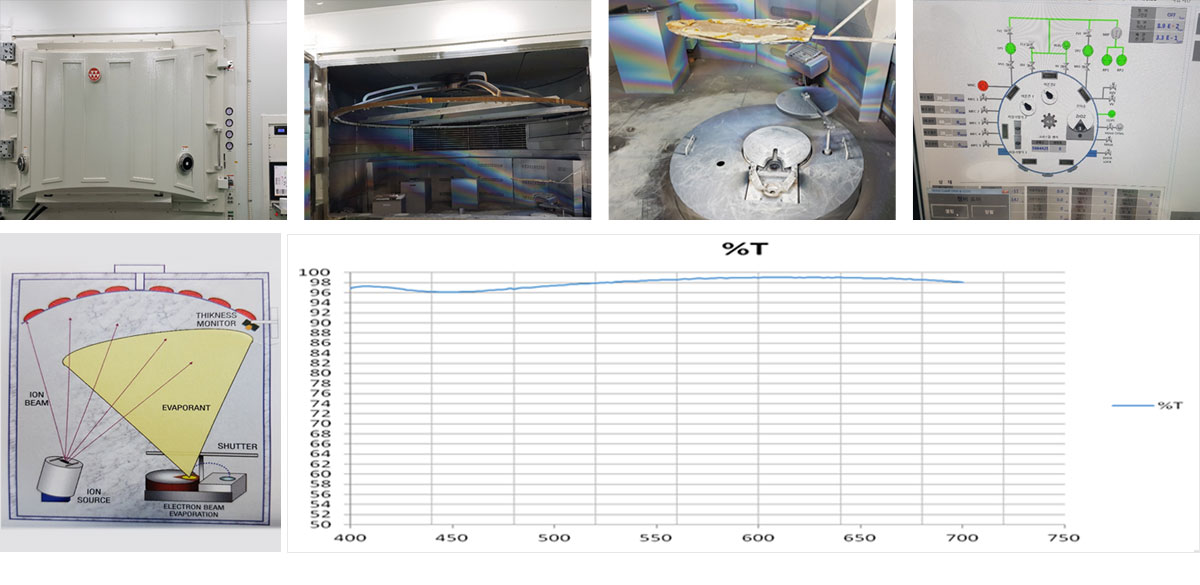

E-BEAM Coating

- Single-Sided Four-Layer Coating

- Double-Sided Eight-Layer Coating

-

Dipping Coating

- Double-Sided Two-Layer Coating

- Double-Sided Four-Layer Coating

Applicable to a single side or both sides over 98 inches!

Applicable to a large area with a maximum size of 4000mm X 2400mm!

In-Line Sputtering AR Coating

SiO2/TiO2 is physically or chemically deposited on the surface of the glass.

▶ Principle and Structure of AR Coating

E-BEAM AR Coating

Designs and Characteristics of Deposition

| Glass |

Chemicals |

Thickness |

| 1 |

sio2 |

0.48 |

| 2 |

tio2 |

0.52 |

| 3 |

sio3 |

0.96 |

| 4 |

tio3 |

2.22 |

| 5 |

sio4 |

0.19 |

| 6 |

tio4 |

1.23 |

| 7 |

sio5 |

2.8 |

| 8 |

AF |

0.1 |

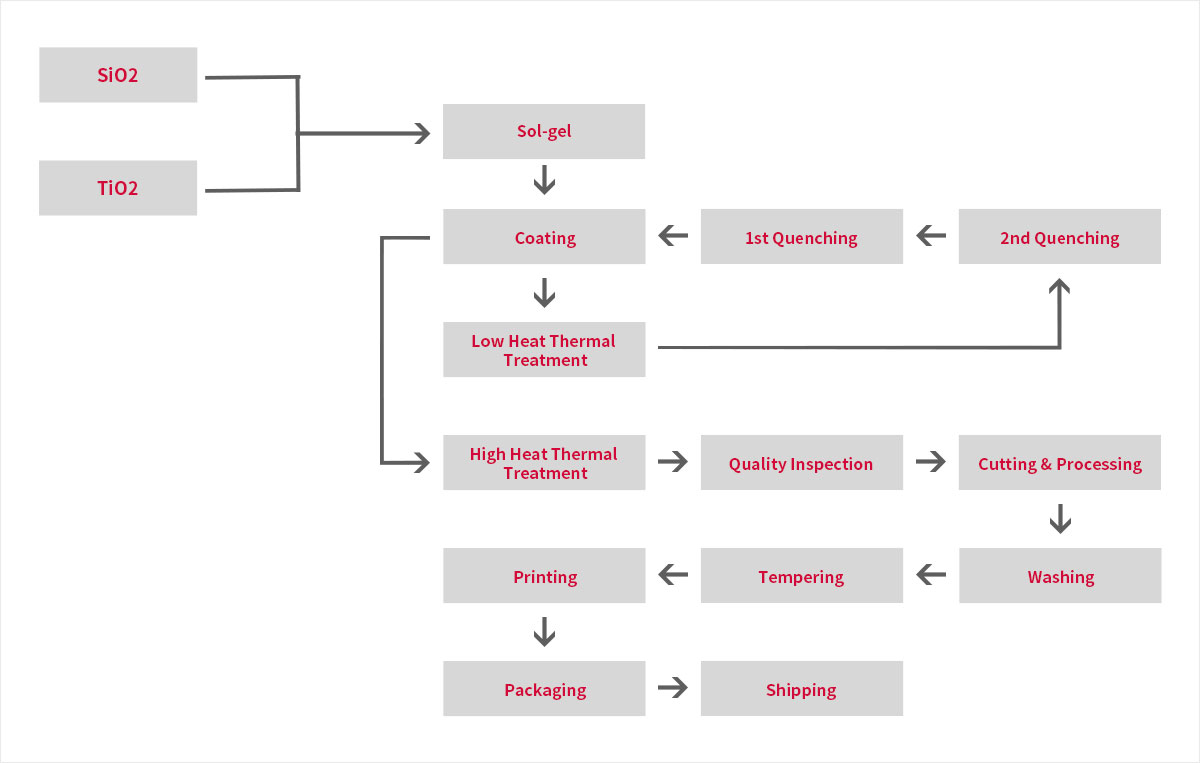

Anti-Reflective Glass (Sol-gel Technique)

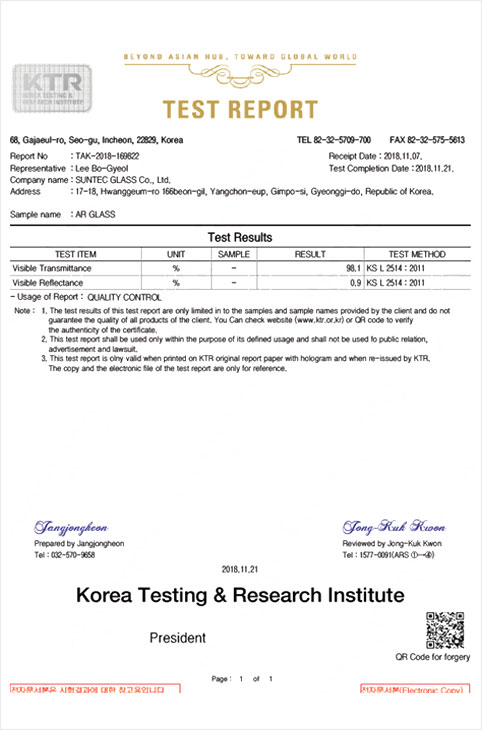

Features of AR Glass of Suntech Glass Co., Ltd Include

- Being resistant to external shocks and scratches—sputtering/E-BEAM

- Not peeling off or deteriorating in high temperature and high humidity environments due to excellent bonding strength between glass and coating layer—sputtering/E-BEAM

- Being alkali-free to prevent deterioration of LCD characteristics

- Being able to coat a large area with a maximum size of 4000mm X 2400mm—sputtering/dipping

- Being resistant to external contaminants and applicable with an anti-fingerprint coating—sputtering/E-BEAM

- Being highly resistant to heat and not being deformed by tempering—sputtering/dipping

- Acting as a filter blocking ultraviolet and infrared rays from the display—sputtering/E-BEAM

- Realizing high-definition videos with high transmittance and stable viewing angles—up to 99% transmittance

- Being able to do optical designs and adjust the number of coating layers or colors, depending on the intended use—sputtering/E-BEAM

- Keeping the characteristics of the display stable by transferring the heat generated inside quickly to the outside with high thermal conductivity—sputtering/E-BEAM

- Being able to apply AG treatment + AR coating + AF coating at the same time—medical/aircraft monitors