Anti-Glare Glass (AG Glass)

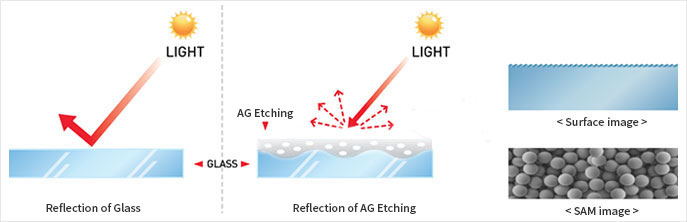

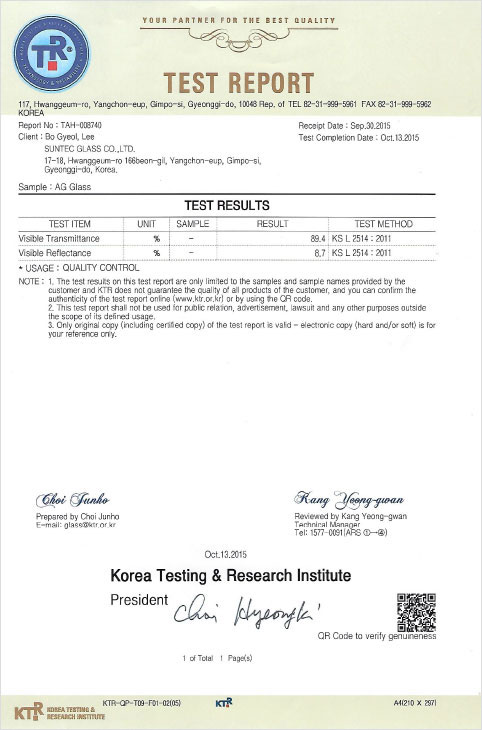

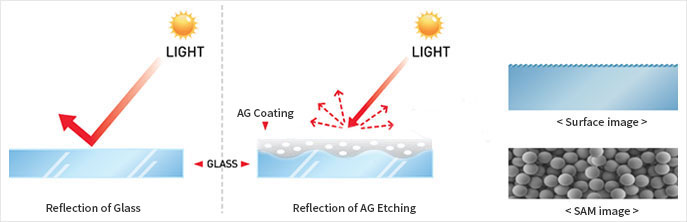

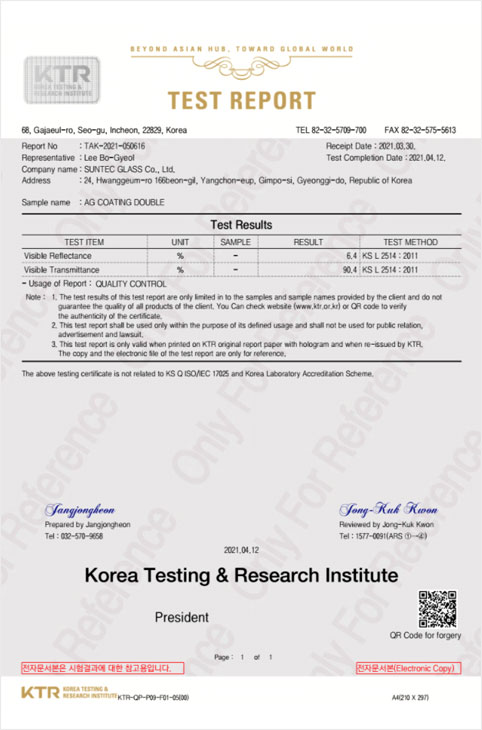

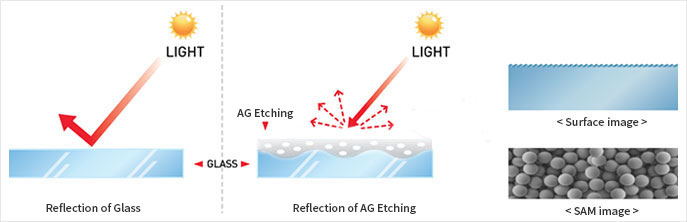

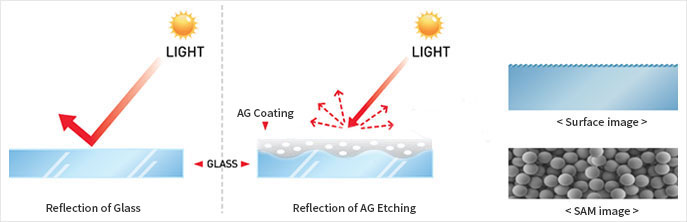

Anti-Glare Glass is a special glass made to artificially control the transmittance and reflectance of light

by chemically etching or coating the glass to create concave-convex structures

on the surface of the glass, allowing the fine particles to scatter light.

Anti-Glare Glass, with no fear of peeling off as it is not a film type, is a glass designed to realize clear

and bright images as well as reduce eye fatigue by preventing reflections, glare, and mirrors

caused by external objects as it has an anti-glare function.

SunTec Co., Ltd. has developed various products by devising treatment methods for Anti-Glare in etching type/coating type/film type.

We can produce single-sided/double-sided Anti-Glare products up to 98 inches using both etching and coating methods,

based on the experience of applying the etching method for more than 15 years and

the coating method for more than 5 years to a number of lines of products, both domestic and overseas.

Anti-Glare Treatments

-

Cheical Etching (Dipping / Spraying)

- AG Etching – Front Side

- AG Etching – Back Siade

- AG Etching – Back Side (Anti-Newoning)

-

Chemical Coating

- AG Coating – Front Side

- AG Coating – Back Side (Anti Newoning)

- AF (Anti-Fingerprint) Coating – Front Side

-

Anti-Glare Film Laminating

- AG Film Laminating – Front Side

- AF (Anti-Fog) Film Laminating – Back Side

Applicable to a single sided or both sides over 98 inches!

Chemical Etching

1) Dipping

2) Spraying

▶ Principle and Structure of Chemical Coating

Chemical Coating

1) AG Coating & AF Coating

▶ Principle and Structure of Chemical Coating

Features of Anti-Glare of SunTec Glass Co., Ltd. Include

- Having no glare at all because the surface of the glass is specially treated with a fine texturing structure—coating/etching

- Having excellent transmittance by increasing the light treatment time after AG treatment of the surface—etching

- Containing no impurities and residues by using a precision cleaner—coating/etching

- Being resistant to external scratches with high surface hardness—coating

- Maintaining the high surface hardness of the glass itself—etching

- Allowing control of roughness, transmittance, and Haze Gloss of the surface of the glass to suit the intended use—coating/etching

- Not peeling off or deteriorating of the particles on the surface of the glass—coating

- Being able to apply to either a single side or both sides of a large area—coating/etching

- Being easy to maintain a subtle appearance—etching

- Being able to additionally apply anti-fingerprint function—coating/etching

- Causing no problems even if the glass touches the panel, as Anti-Newoning function is added to the back side—coating/etching